Introduction

Advancements in Blade Design:

The introduction of cutting-edge materials is reshaping turbine construction. High-strength alloys, ceramics, and innovative coatings are being incorporated into mechanical components, enhancing durability and reducing wear. These materials withstand harsh conditions and extend maintenance intervals, ultimately increasing turbine efficiency.

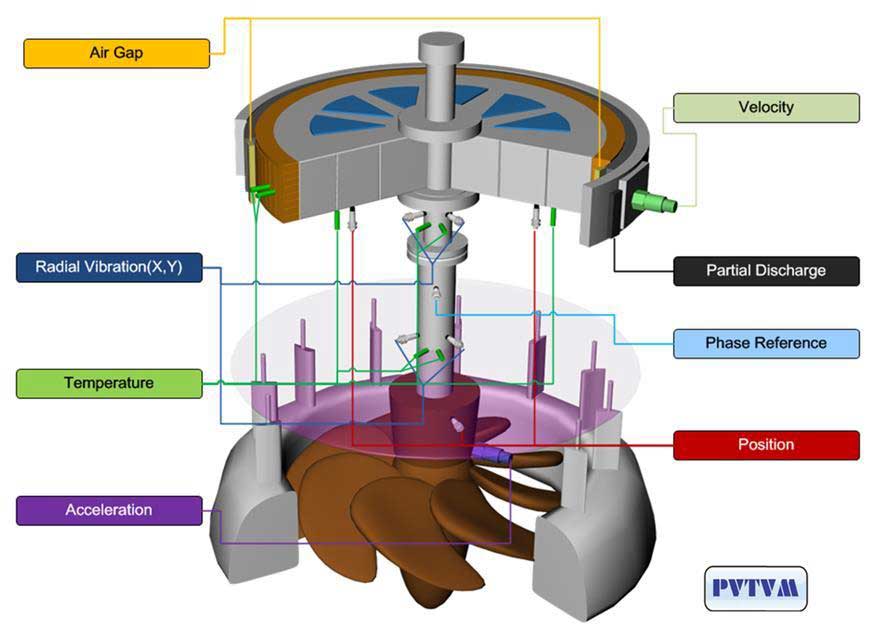

Real-time monitoring and predictive maintenance have become indispensable in optimizing turbine performance. The integration of sophisticated sensors and AI-driven analytics enables early fault detection and prevents potential breakdowns, ensuring uninterrupted operations and reducing downtime.

As the energy industry strives for greater sustainability and efficiency, the continual evolution of turbine technology remains paramount. The commitment to enhancing mechanical components within turbines is pivotal in driving efficiency, reliability, and sustainability in energy generation.

Ghauri Mechanicals, at the forefront of innovative mechanical engineering solutions, echoes the commitment to advancing turbine efficiency. With a focus on precision engineering and cutting-edge technology, Ghauri Mechanicals pioneers the development and integration of high-performance components into turbines. The company’s dedication to research, coupled with a strong emphasis on reliability and sustainability, positions Ghauri Mechanicals as a trusted leader in optimizing turbine mechanisms for maximum efficiency.